Over 50 Years of Freeze-Drying Expertise

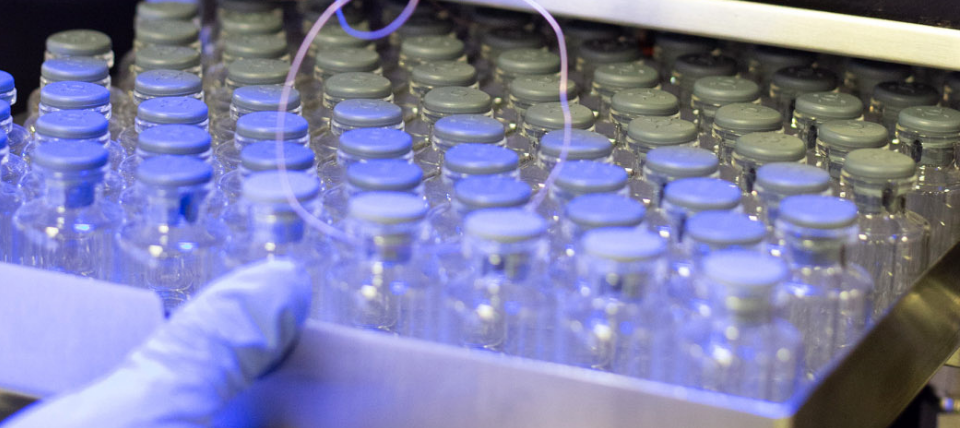

SP has been advancing the science of freeze-drying, or lyophilization, for over five decades, delivering precision, performance, and reliability from the lab to large-scale manufacturing. Our Hull and VirTis lyophilization systems are trusted worldwide for their innovation and quality, helping pharmaceutical, biotech, and research teams achieve consistent, validated results.

With proven engineering, advanced analytics, and GMP-ready features, SP's development, pilot, and production freeze dryers provide the confidence to optimize, scale, and succeed at every stage of development.

Designed with Scalability in Mind

SP freeze dryers are built to grow with your process. The Hull line delivers GMP-ready performance with automation and integrated Process Analytical Technology (PAT) tools such as LyoFlux®, SMART™, TEMPRIS®, and ControLyo®, enabling real-time monitoring, precise cycle control, and reliable scale-up. VirTis systems offer compact, versatile solutions ideal for R&D and small-batch production.

Together, they provide a complete suite of freeze-drying solutions that adapt seamlessly as your needs evolve, supporting confidence in every run.