Frequently used links

Hull LyoConstellation™ S80/S100/S130 Production Lyophilizers

Hull LyoConstellation™ S80/S100/S130 Production Lyophilizers

Hull LyoConstellation™ S80/S100/S130 Production Lyophilizers

If you need a lyophilizer that slots into your fill-finish workflow and is cleanroom ready, Hull LyoConstellation™ S80, S100 and S130 Production Lyophilizers are here to help.

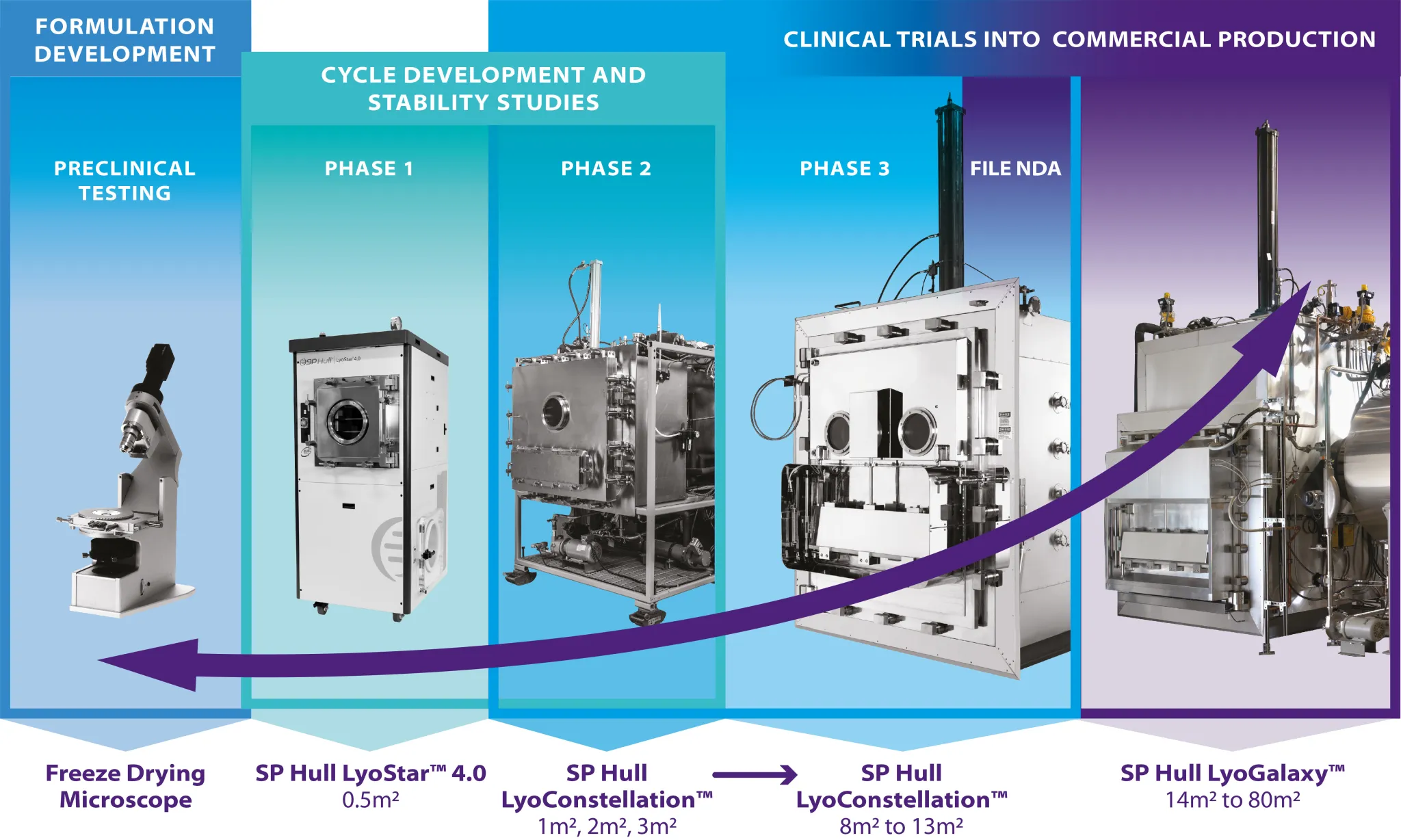

LyoConstellation production lyophilizers build on SP’s reputation as a pioneer of freeze-drying technologies. Ready-to-order, and equipped and controlled as a production system, the LyoConstellation offers a seamless approach to scale-up while being designed for line integration. And, with our comprehensive and innovative range of Line of Sight™ Lyophilization and PAT Tools for your high-value products, we’ve done the hard work, so you don’t have to.

Features & Benefits

- Taking you from start to finish — ideal for cycle development and scale-up to stability, pilot, and clinical batch production, through full aseptic production

- Technologies that ensure quality — full suite of PAT tools and technologies enables Line of Sight approach in cycle development and scale-up for simplified technology transfer, assuring product safety and quality in production

- Validation made easy — validation ports in chamber and condenser as standard, with full documentation package and support available

- Accurate end points — Pirani gauge and capacitance manometer as standard

- Built for demanding lyophilization needs — each of our units can accommodate vials up to 100 mL, so you can develop the most aggressive of freeze-drying cycles safe in the knowledge that you’re using a lyophilizer that works with you

- Full Steam in Place (SIP) & Clean in Place (CIP) execution, with manual/H2O2 option

- Isolator ready with auto locking doors

Line of Sight™ Technologies & PAT Tools

To help you overcome the mounting challenges when scaling up your lyophilization processes, LyoConstellation™ lyophilizers are compatible with our state-of-the-art Line of Sight™ Lyophilization and Process Analytical Technologies (PAT) suite of scalable tools:

- LyoFlux® TDLAS — measure water vapor mass flow with accuracy during freeze-drying

- SMART™ Freeze Dryer Technology — get instant feedback on important product data including resistance, heat flow, and mass transfer

- TEMPRIS® Wireless Sensors — advanced wireless temperature monitoring for the highest quality product, on budget and on time

- ControLyo® Nucleation Technology — take control of your freeze-drying with cutting-edge nucleation technology for precise control of the freezing point