Frequently used links

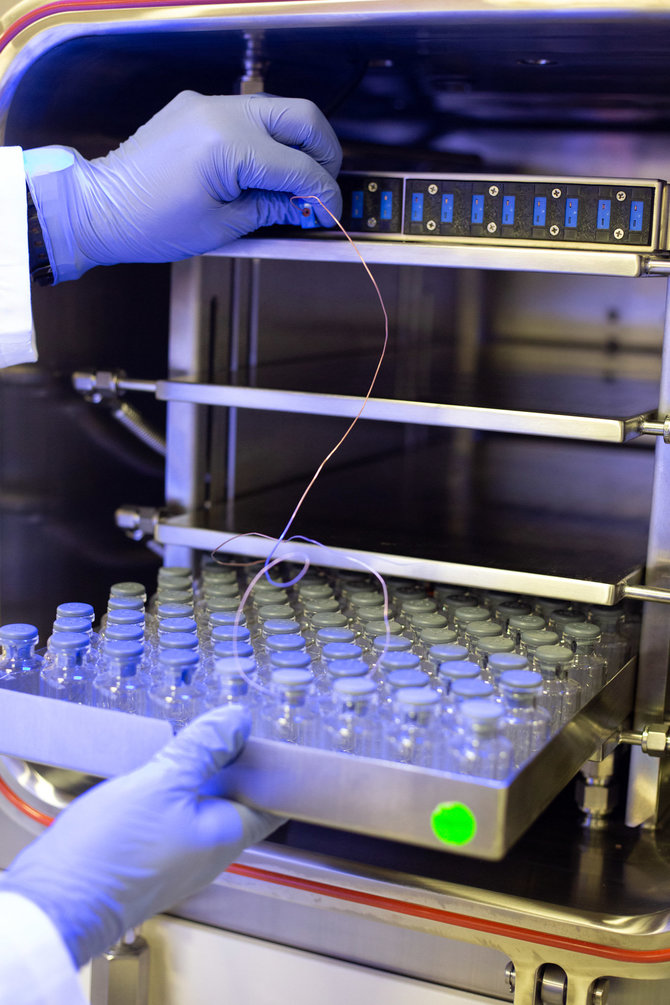

Hull LyoStar® 4.0 R&D/Process Development Freeze Dryer

Hull LyoStar® 4.0 R&D/Process Development Freeze Dryer

Hull LyoStar® 4.0 R&D/Process Development Freeze Dryer

Ideal for rapid lyophilization cycle development, optimization and scale-up, the Hull LyoStar® 4.0 R&D/Process Development Freeze Dryer incorporates the very latest innovations in freeze-drying technology.

Based on a full-scale production freeze dryer to support rapid scale-up, the LyoStar 4.0 is a pilot-scale lyophilizer offering superior shelf mapping and rapid shelf freezing for unmatched process accuracy and reliability. Ensure precise process control and protect your valuable product, with us!

Features & Benefits

- You can never be too informed — LyoStar 4.0 provides more product and process information such as dried layer resistance, heat flow, mass transfer, and how different freezing protocols impact cake resistance

- Easily scalable — advanced, reliable, and scalable lyophilization technologies, along with Process Analytical Technology (PAT) tools, support smooth scale-up from process development through to manufacturing

- Unparalleled uniformity — superior shelf temperature mapping and rapid shelf freezing

- Ecologically sound — reduced carbon footprint with eco-friendlier refrigerant gas

- Cleanroom or isolator integrable — with optional 21 CFR Part 11 compatible software

- Decreases cycle development time and conserves valuable API

- Accessories and consumables for all your lyophilization needs — sample extractor, MVP probes, leveling feet, 21 CFR Part 11

Line of Sight™ Lyophilization & PAT Tools

To help you overcome the mounting challenges when scaling up your lyophilization processes, LyoConstellation™ lyophilizers are compatible with our state-of-the-art Line of Sight™ Lyophilization and Process Analytical Technologies (PAT) suite of scalable tools:

- LyoFlux® TDLAS — measure water vapor mass flow with accuracy during freeze-drying

- SMART™ Freeze Dryer Technology — get instant feedback on important product data including resistance, heat flow, and mass transfer

- TEMPRIS® Wireless Sensors — advanced wireless temperature monitoring for the highest quality product, on budget and on time

- ControLyo® Nucleation Technology — take control of your freeze-drying with cutting-edge nucleation technology for precise control of the freezing point