Frequently used links

ControLyo® Nucleation Technology

ControLyo® Nucleation Technology

ControLyo® Nucleation Technology

Welcome to state-of-the-art controlled nucleation technology with ControLyo® — a novel, patented freeze-drying technology with instant controlled nucleation for ultimate product uniformity.

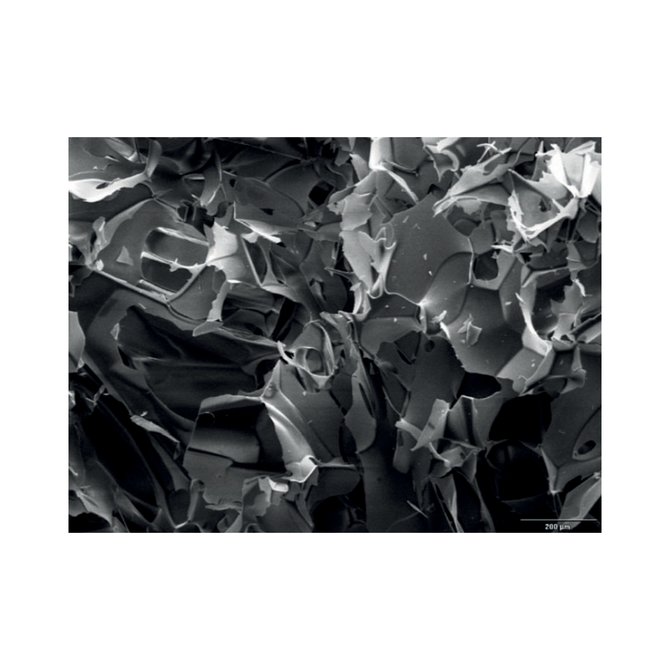

Heterogeneous ice nucleation (crystallization) is one of the biggest challenges in the lyophilization scale-up process. In the absence of controlled nucleation, freezing leads to the formation of random ice crystals, resulting in inconsistent pore sizes, inter- and intra-batch variability, and longer primary drying cycles — all of which negatively impact product quality.

To overcome these challenges, ControLyo® Nucleation Technology enables nucleation at your desired time and temperature, freezing all vials uniformly and consistently to deliver unparalleled product uniformity and reduced drying times— so you can reproduce with confidence.

Features & Benefits

- Improved cake appearance and morphology — no visible collapse or shrinkage thanks to an increase in cake pore size and subsequent reduction in dry layer resistance

- Conforms to the regulatory framework required for Quality by Design (QbD) by controlling process inputs

- Dry faster — reduce primary drying time by 3% for every 1 ℃ increase in nucleation temperature

- Unlike other similar technologies, ControLyo does not require a formulation change or the introduction of foreign material

- No need to purchase additional freeze-drying equipment and retrofits into most existing commercial dryers

- Reproduce results with ease — replicate from one freeze dryer to another, enabling more efficient scale-up

- Eliminate freezing stress — reduce protein aggregations for better stability of protein formulations