-

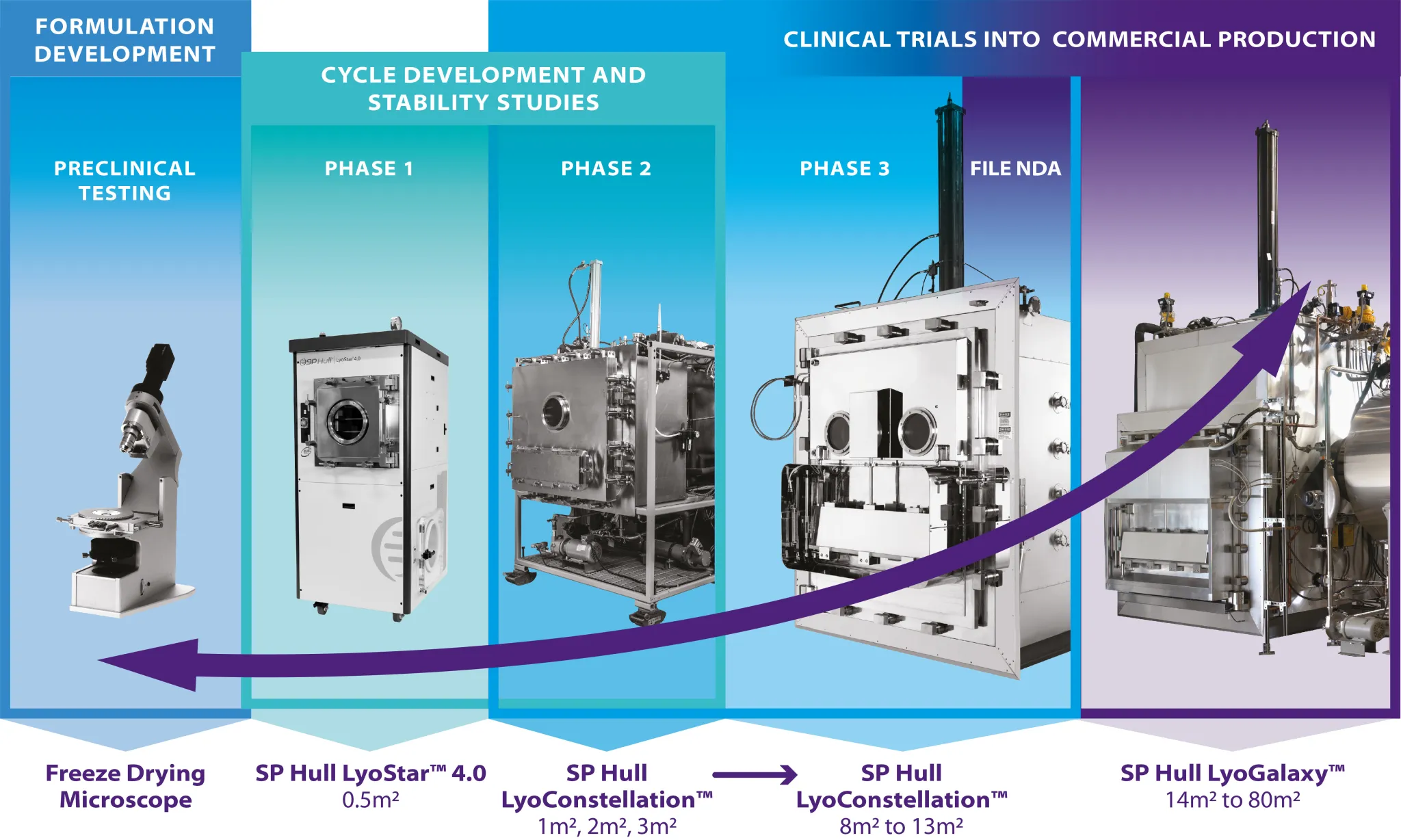

Products Pharmaceutical Processing Equipment Fill-Finish / Aseptic Processing Equipment Development, Pilot & Production Freeze Dryers Lyophilization Technology & PAT Tools

-

Applications

Find Products by Applications & Industries

- Brands

-

Learning Lab

Explore the Learning Lab

- Service & Support

-

About Us

Learn more about SP

Skip to content

Frequently used links