-

Products Pharmaceutical Processing Equipment Fill-Finish / Aseptic Processing Equipment Development, Pilot & Production Freeze Dryers Lyophilization Techology & PAT Tools

-

Segments

Find Products by Applications & Industries

- Brands

-

Learning Lab

Explore the Learning Lab

- Service & Support

-

About Us

Learn more about SP

Frequently used links

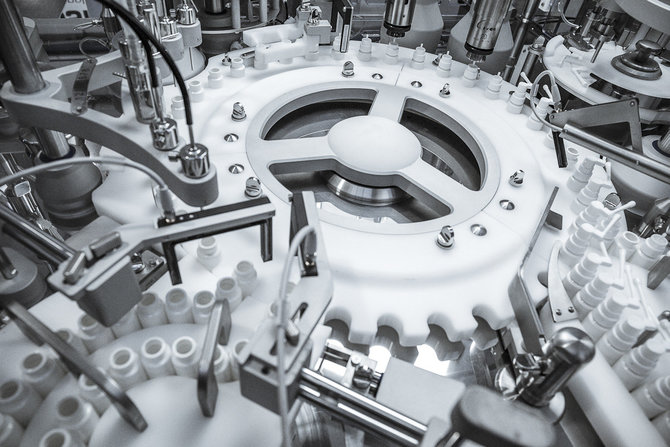

SP i-Dositecno Nasal Spray Filling Machine

For a nasal spray production fill-finish solution that offers unparalleled versatility, look no further! The SP i-Dositecno BI and MI Nasal Spray Filling Machines simplify your manufacturing workflow to enable accurate and consistent rotary filling, stoppering and capping. With simple servo-driven motion-controlled design they can fill up to 50 or 200 units per minute (upm).

- Cleanroom ready

- Fully compliant – 21 CFR Part 11 compliant integrated software and IQ/OQ validation packages available

- Versatile – filling volumes ranging from 100µL to 500 mL

Overview

At SP, we’re translating years of fill-finish experience into high-quality equipment that streamlines your manufacturing processes, mitigates risk, and gets your product to market faster. The SP i-Dositecno BI and MI Nasal Spray Filling Machines offer the dependable sterility, accuracy, and speed essential for pharmaceutical manufacturing whilst meeting the highest quality regulations, including cGMP, Annex 1, and regulatory agencies such as the FDA.

Versatility as standard – When your products need to be supplied in different container sizes and formats, you need a filling machine that matches that diversity. Our Nasal Spray Filling Machines offer full versatility, filling bulk containers and simplifying manufacturing operations where multiple container closures are used.

Consistency is key – Statistical sampling or 100%, non-destructive In-Process Weight Control (IPC) with minimal reduction in processing speeds, ensures superior accuracy and repeatability throughout the entire batch.

Our SP i-Dositecno BI and MI Nasal Spray Filling Machines offer features that help to streamline your workflow:

- Built to cGMP and compliant to GAMP5

- Easily process multiple vial formats thanks to high-quality Polyoxymethylene Copolymer (POMc) change parts for quick changeover

- Aseptic liquid dosing system by peristaltic pump or ceramic / SS rotary piston, micro-dose and solid powder filling by micro-auger for exceptional accuracy and precision

- Servo-driven star wheel transport of containers and filling nozzles

- Available with up to 2-channel pick and place for tips and caps

- Designed with one or two filling nozzles supported by servo-driven motor

- Mechanical unscrambler to organize and feed plastic containers up to 500 mL

- Dedicated hopper to increase automatic container feed

- Feeding system prepared for tanks or bag holder inside the machine

All SP i-Dositecno BI and MI Nasal Spray Filling Machines come complete with Siemens or Allen Bradley PLC-controlled servo motors that allow you to automatically set the output rate, height, and water/air flow for each vessel size. With help from our product portfolio experts and dedicated engineers, you can configure the BI or MI Nasal Spray Filling Machines to meet your exact needs.

Application Examples

- Nasal Spray

Features & Benefits

- Versatile – many options to incorporate into the line such as 100% IPC, PEEK change part materials, nitrogen flush, idle wheel crimping with vertical force monitoring, CIP/SIP

- Project Management and optional validation assistance, Installation Qualification (IQ) and Operational Qualification (OQ) included as standard

- Ultimate product protection – can be integrated with open restricted access barrier systems (RABS), closed RABS and isolation technology