Frequently used links

Hull Freeze Dryer Loading & Unloading Systems

Hull Freeze Dryer Loading & Unloading Systems

Hull Freeze Dryer Loading & Unloading Systems

Designed for advanced aseptic pharmaceutical processes involving lyophilization, the Hull Freeze Dryer Loading & Unloading Systems are innovative, high-performing, and flexible, reducing your overall processing times for improved productivity and greater cost efficiency. Our systems ensure operator and product always remain protected, and, with bridge and transfer plates that always operate within the aseptic environment, you can be sure that GMP standards are always adhered to.

With help from our product portfolio experts and dedicated engineers, you can configure Hull Loading & Unloading Systems to meet your exact application needs with two available models:

- Hull RxR-36 Row-by-Row Freeze Dryer Loader — perfect for full line vial, high-speed applications with loading speeds of up to 400 vials per minute

- Hull SALS-30 Semi-Automatic Freeze Dryer Loader — an ideal replacement for manual freeze dryer loading with its narrow profile, small to medium batch vial handling, and loading speeds of up to 70 vials per minute

Features & Benefits

- Easy decontamination — designed to completely expose the surface during the decontamination process

- Reduced or zero operator intervention — only through glove ports to optimize GMP aspects of freeze dryer loading

- Fully compliant with latest cGMP standards — the bridge plate and transfer plate always operate within the aseptic space

- Ideal for containment and sterility — designed to protect product from operators to ensure sterility and to contain potent products to protect operators

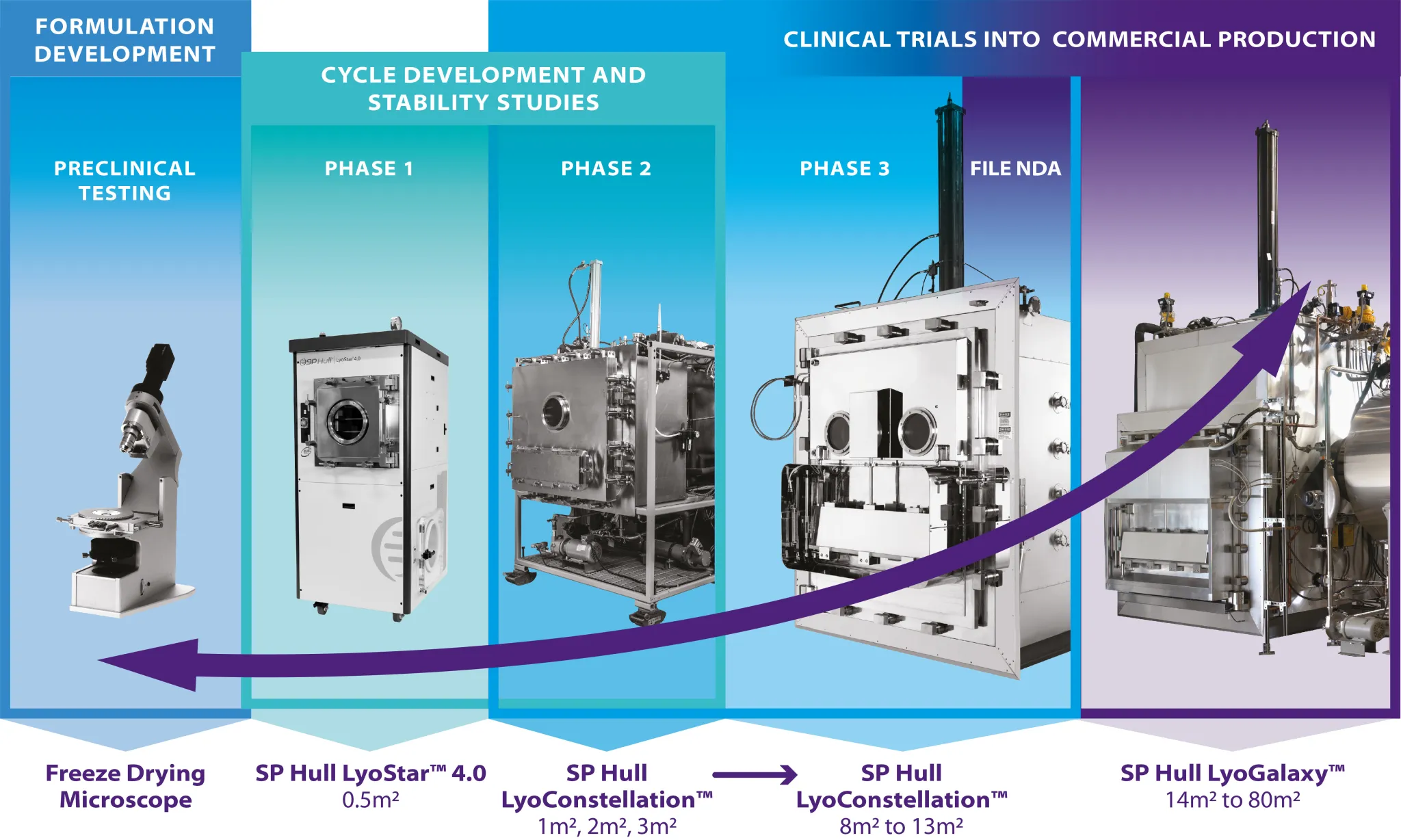

- Seamless integration — Hull Freeze Dryer Loading & Unloading Systems offer flexible solutions for small batch and high-speed applications and the option to integrate with the Hull LyoConstellation range of development, pilot, and production freeze dryers

Applications

Specifications

-

Out-Feed (RxR-36 Only) & In-FeedConveyor

-

Vial Diameter16mm up to 58 mm (2-100mL Vials)

-

ThroughputUp to 400 x vials/min

-

Utility Requirement208 volt, three phase, 60 Hz, 30 amps