Miniaturization in freeze drying is a relevant topic due to the limited availability and costs of API, especially in early development phases. A mini-freeze dryer (LyoCapsule™) consists of a small cylindrical inner chamber intended to freeze dry a reduced number of vials (typically seven 20R vials) and utilizes wall temperature control to emulate heat and mass transfer conditions typically encountered in larger scale. It is equipped with a full suite of process analytical technology (PAT) tools facilitating process development and successful scale-up / scale-down. Manometric Temperature Measurement (MTM) has already been proven as a key technology for the monitoring of freeze drying processes and evaluation of critical process and product parameters. Therefore, it serves as a useful tool to facilitate transfer of cycles between different freeze dryers and scales. This webinar focuses on the applicability of MTM and SMART™ in the LyoCapsule™ freeze dryer, illustrated by several examples (such as wall temperature adjustment, amorphous and crystalline formulations and minimum load required for reliable values). Finally, the development of a robust and reproducible cycle in the mini-freeze dryer supported by advanced PAT tools is exemplarily demonstrated and cycle transfer to larger units is discussed. Presented by Dr. Alexandra Braun, PhD Scientist at GILYOS

-

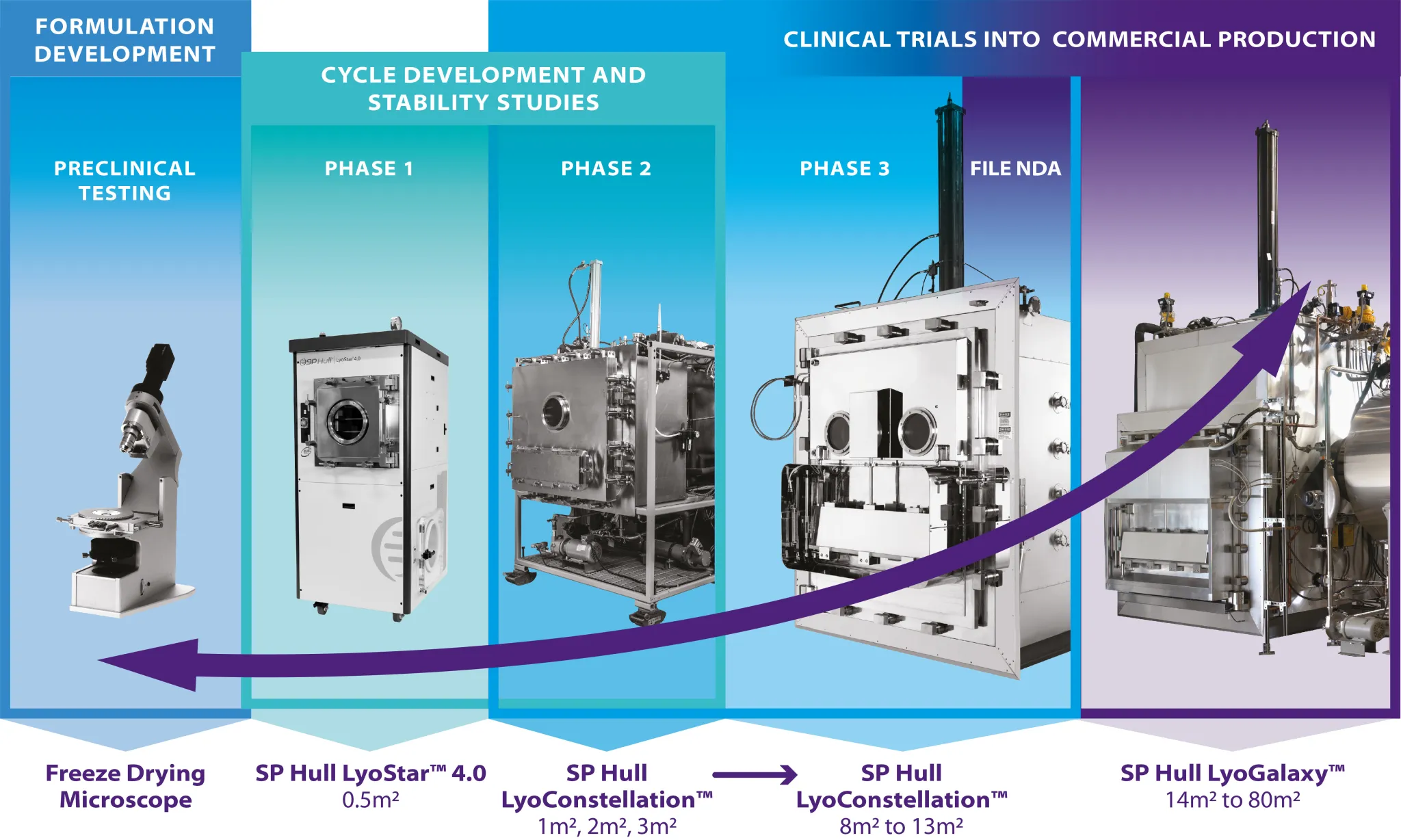

Products Pharmaceutical Processing Equipment Fill-Finish / Aseptic Processing Equipment Aseptic & Production-Scale Freeze Dryers Lyophilization Technology & PAT Tools

-

Applications

Find Products by Applications & Industries

- Brands

-

Learning Lab

Explore the Learning Lab

- Service & Support

-

About Us

Learn more about SP