-

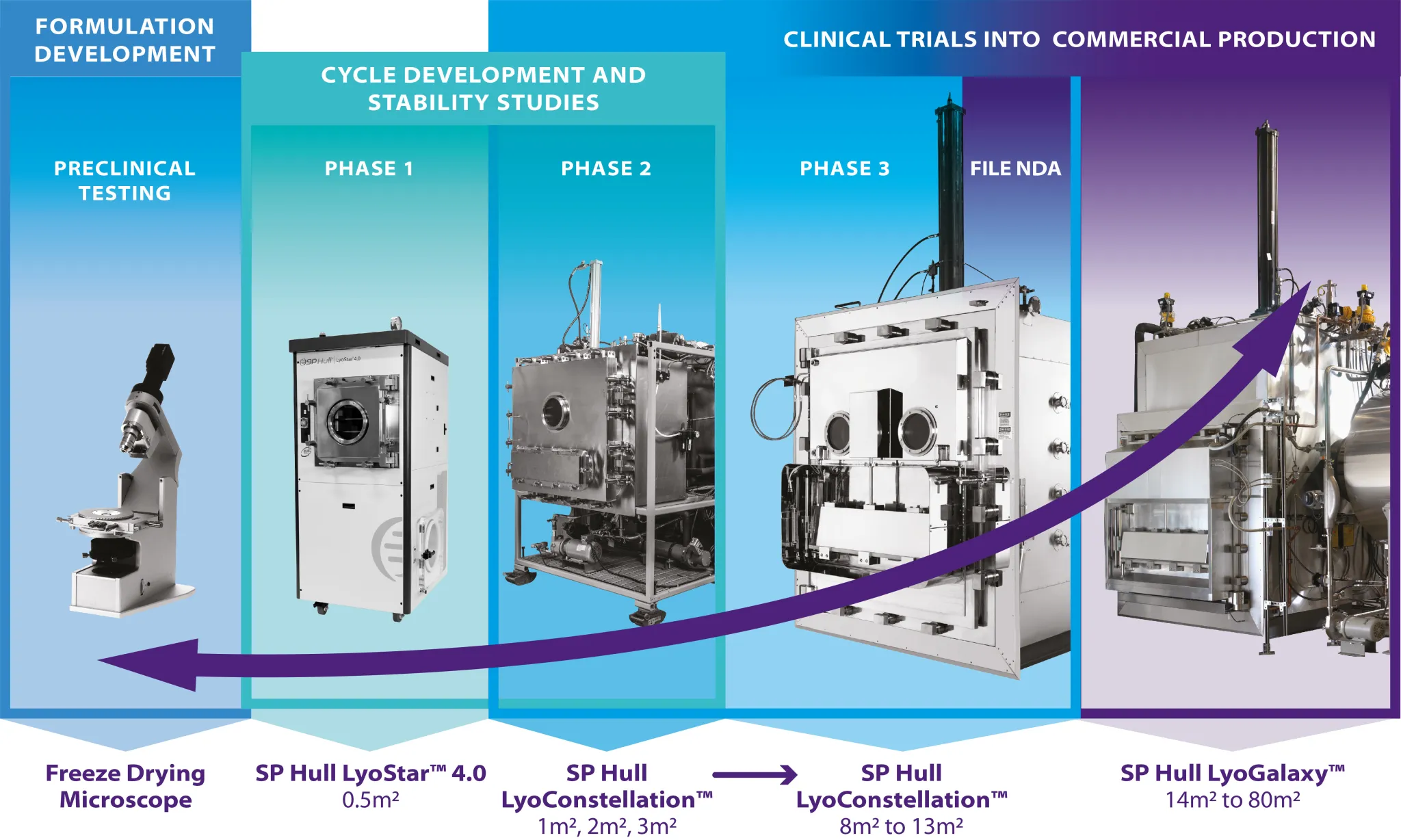

Products Pharmaceutical Processing Equipment Fill-Finish / Aseptic Processing Equipment Aseptic & Production-Scale Freeze Dryers Lyophilization Technology & PAT Tools

-

Applications

Find Products by Applications & Industries

- Brands

-

Learning Lab

Explore the Learning Lab

- Service & Support

-

About Us

Learn more about SP

Frequently used links

Product Finder

Product Type

Benchtop Solvent Evaporators

Development, Pilot & Production Freeze Dryers

Fill-Finish / Aseptic Processing Equipment

Laboratory Glassware Washers

Lyophilization Technology and PAT Tools

Research & Pilot Freeze Dryers

Stability Testing

Thermal Management Solutions

Segment/Industries

Aerospace

Agriculture

Analytical Chemistry/BioChemistry

Animal Health

Automotive

Biopsy Labs

Biotechnology

CRO/CDMO

Cartilage & Muscle Research

Chemical Manufacturing

Contract Manufacturing

Cosmetics

Defense

Diagnostic

Differential Scanning Calorimeters

Environmental

Environmental Testing

Food/Beverage

Frozens Labs

General Laboratories

Health Services/Medical

Horse & Cattle Cryolabs

Hospitals

Laboratories

Manufacturing

Medical Devices

Metallurgical Labs

MoHS Labs

Museums

NMR Labs

NMR Manufacturers

Nutraceuticals/Natural Products

Oil and Gas

Petrochemical

Pharmaceutical

Quality Control/Testing

Semiconductor

Steel Manufacturing

Steel Testing Facilities

Tissue

Transgenic Labs

Universities

Universities - Biochemistry

Universities - Chemistry

Universities - Chemistry & Biochemistry

Universities- Embryology & Biology

University - Chemistry & Biology

University/R&D

University/Research and Development

Vacuum Pump Manufacturers

Veterinarians

Water Treatment

Application

Vaccines

Antibody Drug Conjugates (ADCs)

Bulk API

Potent Compounds

Diagnostic Kits

Tissue

Post purification

Oligo synthesis

Reagents

Peptides and proteins

Calorimeters

Rotary Evaporators

Heat Exchanger for Temperature Testing

Lasers

Reaction Vessels

Medicinal chemistry/ PROTACS

crystallagraphy

ADME & DMPK

Vacuum Pump Protection

Vacuum Ovens

Parylene Coating

Temperature Testing Electronics

Temperature Cycling

Fiber Optics

Telecommunications

RF Microwave

Failure Analysis

Metal Testing

General Lab Use

Electropolishing

Medical Devices

Media kitchens

core facilities

clinical labs

glassware washing

Seeds

Artifacts

Books

Peptides

HPLC Fractions

Concentration for analysis

Cleaning validation

Embryo Freezing

Compouind Management

Natural products research

Molecular biology

Clinical

Parylene

Cold Traps

Dewers

Gas Chromatography

Bending Beam Rheometer

Asphalt Testing

Cold Traps Corrosive Protection

Snap Freezing Tissue Samples

Cryostats

Gene & Protein Expression

Histology

Pathology

NMR

X-Ray Diffraction

Electronic Testing

ICH/FDA Stability Testing

Shelf-Life Testing

Acceleration Studies

CryoFreezing

InVivo

Stem Cells

Vacuum Chambers

Cold Plate

Material Testing

Brand

FTS

Genevac

Hotpack

Hull i-Dositecno

Virtis