Frequently used links

SMART™ Freeze Dryer Technology

SMART™ Freeze Dryer Technology

SMART™ Freeze Dryer Technology

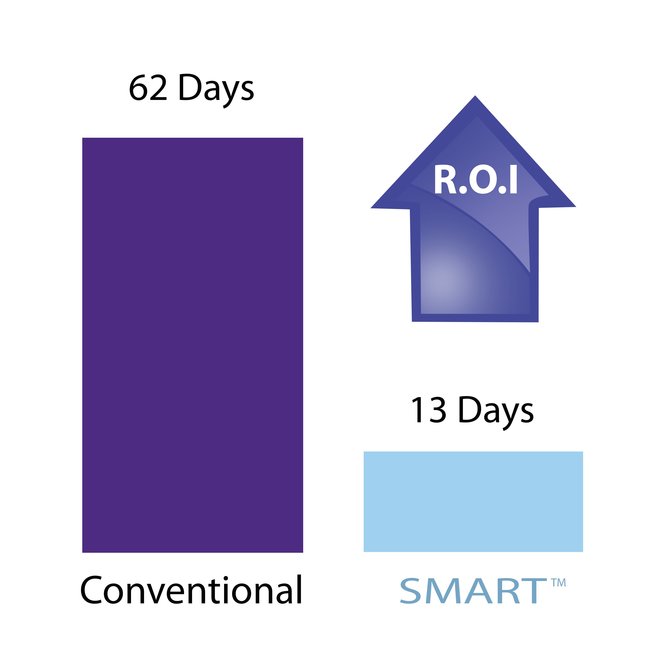

Whether you’re a lyophilization expert or freeze-drying novice, scientist-developed SMART™ Freeze Dryer Technology can help you to develop new cycles quickly and with ease, giving instant feedback on important and previously unattainable product data — for a greater return on your investment.

Because we understand that knowledge is power, our innovative SMART technology includes patented Manometric Temperature Measurement (MTM) — and our own innovative AutoMTM if you’re looking to run your own pre-determined cycle — allowing you to determine cake resistance, product temperature, and other critical parameters at the ice interface.

Features & Benefits

- More walk-away time — automate and minimize freeze-drying cycle development time so you can invest more time looking into formulation strategies to maximize product effectiveness

- Simplified transfer of freeze-drying cycles to your production freeze dryer

- Understand more about your product and the obstacles and opportunities in its lyophilization cycle development

- Increase ROI with greater throughput and optimized cycles

- Work more efficiently — condenser coil configuration helps maximize condenser efficiency for superior operational performance, economical energy usage, and reduced maintenance costs

- Options for cleanroom configurations, with 21 CFR Part 11 package available as an added extra