Tempris® Wireless Sensors

Tempris® Wireless Sensors

Tempris® Wireless Sensors

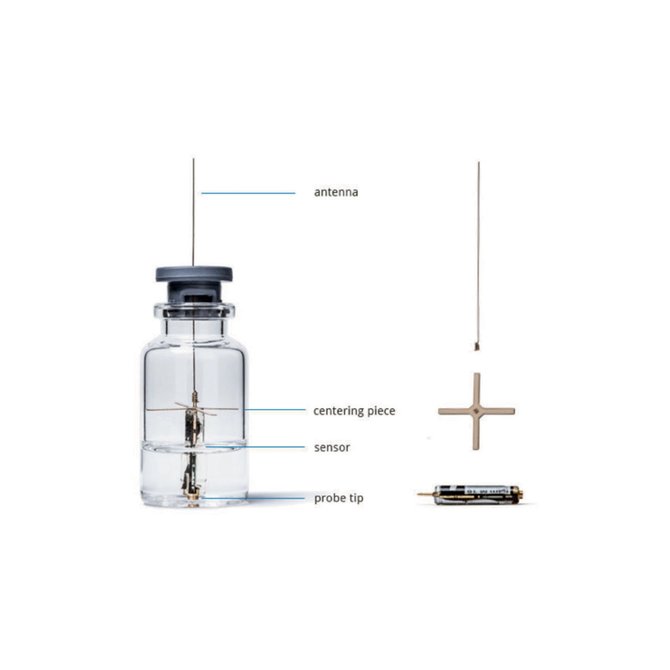

Forget time-consuming traditional temperature measurement approaches and get freeze-drying accuracy and efficiency with Tempris® Wireless Sensors — your trusted process analytical technology.

Developed in collaboration with leading pharmaceutical companies and universities in Europe and the United States, Tempris Wireless Sensors offer real-time product temperature monitoring, hot and cold spot monitoring, lyo-cycle optimization, options for scale-up and transfer, and data for regulatory submission.

Eliminating the need for difficult-to-position thermocouple wires that cause issues with product sterility and accurate data collection, Tempris Wireless Sensors are fully compatible with cleanroom systems protected by Restricted Access Barriers (RABs) — for unparalleled product protection throughout the entire production process.

Image supplied by kind permission of Tempris® GmbH.

Features & Benefits

- Prevents contamination — wireless, battery-free, cleanable, and sterilizable sensors for use in aseptic manufacturing

- Compatible with automatic loading systems unlike traditional wired systems

- Reliable data for process monitoring — direct product temperature measurement with hot and cold spot monitoring means you learn more about the critical parameters contributing to lyophilization success

- Scalable technology — can be used in any freeze dryer, simplifying the transition from development to production

- Easy installation — Tempris Wireless Sensors are easily positioned after pre-sterilization saving you time and money